Scientists at the Massachusetts Institute of Technology (MIT) have created a two-dimensional polymer with the strength of a steel alloy and the weight of plastic. Previously, the development of such a substance was considered unrealistic.

The resulting polymer, called 2DPA-1, is capable of self-folding into 2D sheets, which distinguishes it from other similar substances that form one-dimensional chains. In the future, it will be possible to produce it on an industrial scale. The polymer can be used to form light and high-strength coatings for automotive elements and smartphones. In addition, it will find application in construction. Developers are already going to apply for patents. More details about the technology can be found here.

Polymers (all plastics) are made up of monomers - individual blocks. Polymers grow by attaching molecules at their ends. At the end of the formation, the polymers are able to acquire the required shape by injection molding. Previously, monoparticles could grow in three directions, but the researchers suspected that it was possible to simulate the growth of polymers in a purely single plane. In this way, ultra-strong and small in mass materials would be obtained.

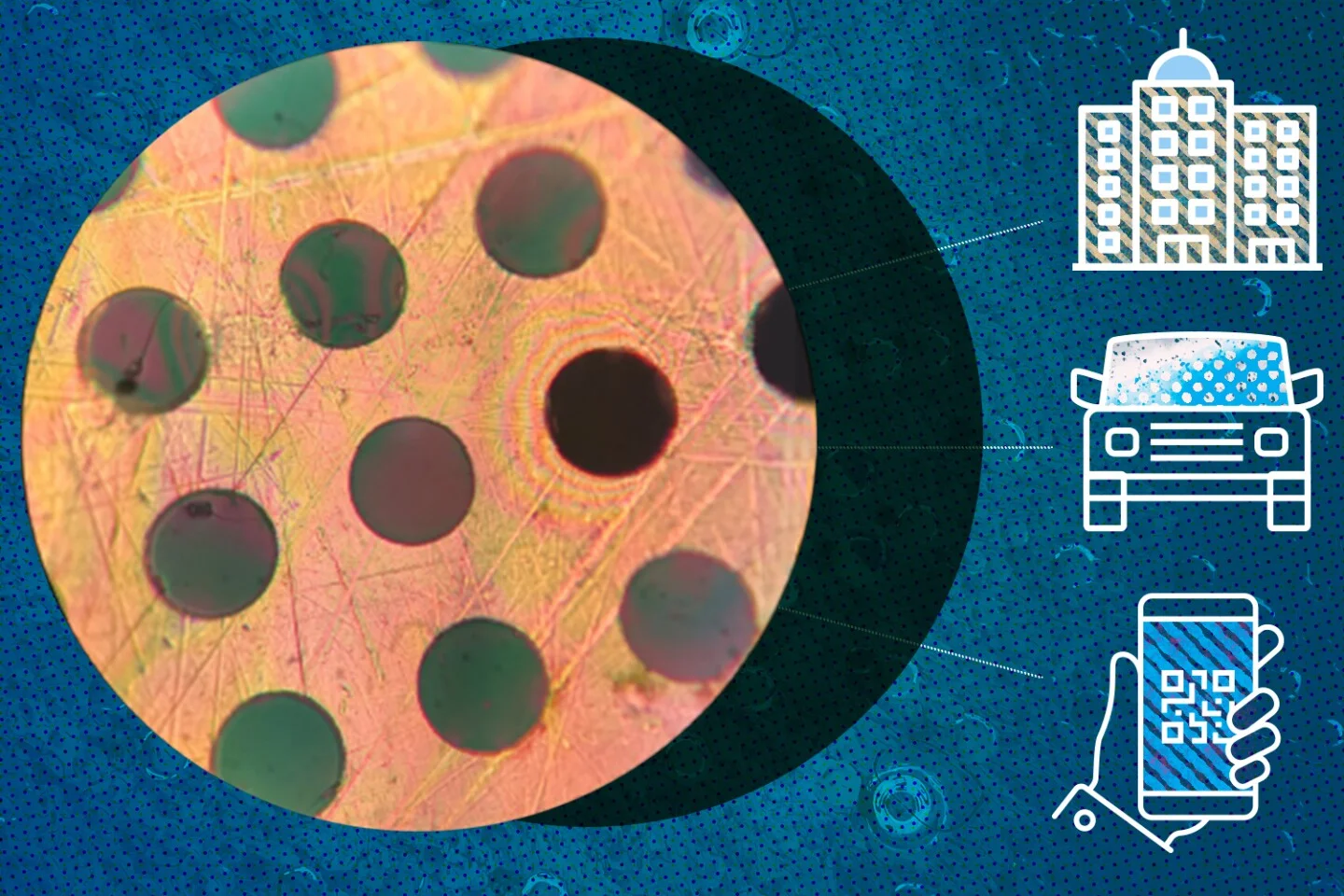

MIT Carbon P. Dubbs professor of chemical engineering Michael Strano and his assistants have developed a new polymer formation process that produces a two-dimensional polyaramid sheet. Melamine molecules, structurally consisting of carbon and nitrogen atoms, became monomers for the polymer. With certain inputs, monomers are only able to grow in 2D to form discs. Further, disc-shaped elements are superimposed one on top of the other, holding by means of a hydrogen bond.

According to Strano, the monomers themselves collect in solution, followed by synthesis and spin-coating of the films. The result is a heavy-duty material with an elastic modulus 4-6 times higher than that of armored glass. The yield strength (the load that must be applied to break) of the material is twice that of steel alloys. In addition, the polymer does not allow liquids and gases to pass through.

The resulting polymer, called 2DPA-1, is capable of self-folding into 2D sheets, which distinguishes it from other similar substances that form one-dimensional chains. In the future, it will be possible to produce it on an industrial scale. The polymer can be used to form light and high-strength coatings for automotive elements and smartphones. In addition, it will find application in construction. Developers are already going to apply for patents. More details about the technology can be found here.

Polymers (all plastics) are made up of monomers - individual blocks. Polymers grow by attaching molecules at their ends. At the end of the formation, the polymers are able to acquire the required shape by injection molding. Previously, monoparticles could grow in three directions, but the researchers suspected that it was possible to simulate the growth of polymers in a purely single plane. In this way, ultra-strong and small in mass materials would be obtained.

MIT Carbon P. Dubbs professor of chemical engineering Michael Strano and his assistants have developed a new polymer formation process that produces a two-dimensional polyaramid sheet. Melamine molecules, structurally consisting of carbon and nitrogen atoms, became monomers for the polymer. With certain inputs, monomers are only able to grow in 2D to form discs. Further, disc-shaped elements are superimposed one on top of the other, holding by means of a hydrogen bond.

According to Strano, the monomers themselves collect in solution, followed by synthesis and spin-coating of the films. The result is a heavy-duty material with an elastic modulus 4-6 times higher than that of armored glass. The yield strength (the load that must be applied to break) of the material is twice that of steel alloys. In addition, the polymer does not allow liquids and gases to pass through.

Login or register to post comments

Comments 0